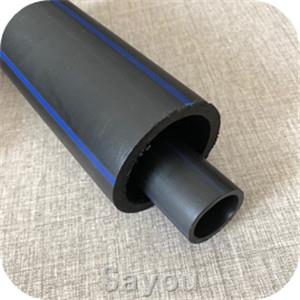

PE PIPE

| Name | High Density Polyethylene (HDPE) Pipe |

| Material | Sinopec's 100% high density polyethylene |

| Color | Black with blue line |

| Diameter | DN 20mm-1000mm |

| Pressure | PN6 PN8 PN10 PN12.5 PN16 |

| Thickness | 2mm-60mm |

| Surfaces | Smooth, clean and free from scoring |

| Length | The length of HDPE pipes in coil for diameter 32mm and below will be 200 meter/rolls. |

| The length of HDPE pipes for diameter 32 mm and above shall be 6m or 12m. |

Our HDPE pipe is recognized in the industry for its zero leak rate, corrosion resistance, and long life expectancy, excellent flow capacity, reduced installation cost, lightweight and flexible.

1.Leak Free

Polyethylene pipe is normally joined by heat fusion. Butt, socket, sidewall fusion and electrofusion create a joint that is as strong as the pipe itself, and is virtually leak free.

2.Corrosion Resistance

HDPE pipe has excellent corrosion resistance against acids, bases, salts and any known corrosive soil or water condition. you don’t have to worry about tuberculation, or the need for costly lining, wrapping, coating or cathodic protection.

3.50 Years Service Time

HDPE pipe is a safe and durable product ideal for your piping infrastructure. The service life of HDPE is estimated to be 50 years, depending on application, design and installation.

4.Excellent Flow Capacity

Polyethylene pipe has a smooth interior providing less drag and a lower tendency for turbulence at high flow. Its superior flow characteristic eliminates scaling and pitting to preserve its form for consistent flow throughout the pipe’s entire service life.

5.Reduced Installation Cost

HDPE pipe is lightweight, flexible, and comes in long lengths, allowing for easier and convenient installation. Because of its flexible nature, it reduces the use of fittings.

6.Lightweight and Flexible

Polyethylene pipe is produced in straight lengths or in coils. Made from materials about one-eighth the density of steel, it is lightweight and does not require the use of heavy lifting equipment for installation.

Polyethylene piping is a cost effective solution for a broad range of piping problems in municipal, industrial, marine, mining, and agricultural applications. Our pipe has been utilized in pressure water systems, sewer and waste water, mining, and irrigation.

HDPE pipe provides effortless installation utilizing the newest technology available today. our pipe can be joined by various heat fusion methods such as electrofusion, socket fusion, butt fusion and saddle fusion.

| PN | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa |

| SDR | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

| DN | EN(mm) | EN(mm) | EN(mm) | EN(mm) | EN(mm) |

| 20 | 2 | 2.3 | |||

| 25 | 2.3 | 3 | |||

| 32 | 2.3 | 2.4 | 3 | ||

| 40 | 2.3 | 2.3 | 3 | 3.7 | |

| 50 | 2.3 | 2.9 | 3.7 | 4.6 | |

| 63 | 2.3 | 2.5 | 3.6 | 4.7 | 5.8 |

| 75 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 |

| 90 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 |

| 125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.1 | 15 | 18.7 | 23.2 | 28.6 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | - |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | - |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | - |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | - |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | - |

| 630 | 24.1 | 30 | 37.4 | - | - |

| 710 | 27.2 | 33.9 | 42.1 | - | - |

| 800 | 30.6 | 38.1 | 47.4 | - | - |

{{ title }}

{{ description }}